Wheel Mounted Plants

- Home

- Wheel Mounted Plants

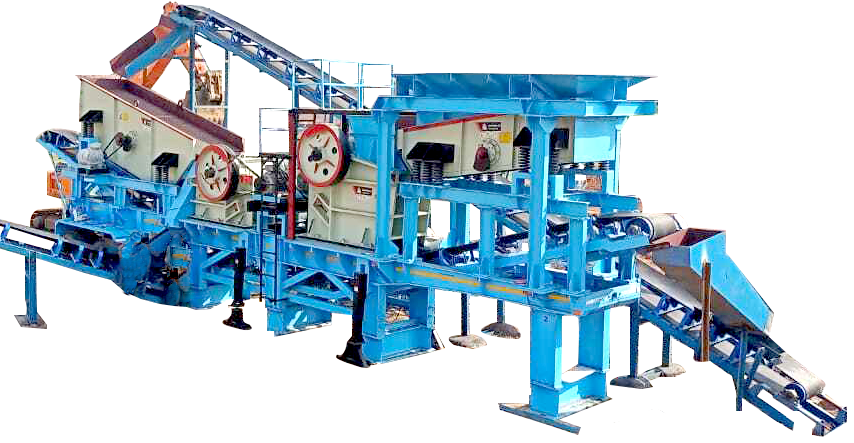

Wheel Mounted Plants

Mobile Crushing And Screening Equipments

BPA designs and manufactures a diverse product portfolio of portable crushing and screening plants for increased portability and flexibility on site. Our portable crushing and screening units are flexible, durable and give class-leading productivity. Many of these units combine both primary, secondary and tertiary crushing, as well as screening, in a single unit.

These Agarwalla make wheel-mounted semi-mobile crushing and screening units combine both primary and secondary crushing, as well as screening, in a single unit. It’s a full production unit on one chassis, giving you maximum productivity with a single investment.

Range starts from a standard 30 TPH single stage unit and goes all the way upto 200 TPH multi stage crushing unit with optional independent chassis mounting for ease of integration with existing crushers of end users.

Mobile Jaw Crusher

Agarwalla Portable jaw crushers are wheel-mounted rock crushing machines engineered for primary crushing applications. Suitable for crushing hard and soft rock, such as granite, basalt, limestone, and as well recycled materials, portable jaw crushers are the optimal choice if you want to move the crushing plant from one site to another periodically.

They are easily transportable between production sites and often utilised in aggregates production and recycling applications.

ll units are built for durability and constructed from a robust heavy duty chassis frame which is fully assembled on a single trailer and mounted on double axle chassis. Thus simple, yet effective design includes many benefits for quick set-up and ease of maintenance, resulting in more uptime and higher productivity.

SALIENT FEATURES of Mobile Jaw Crusher

Ideal nip angle for smooth material flow

Ideal nip angle for smooth material flow, high reduction efficiency and single-toggle operation with a deep crushing chamber.

Easy setting adjustment

Easy setting adjustment for simple and efficient operation.

With by-pass chute

With by-pass chute to divert grizzly fines to discharge or optional reject cross conveyor for removing of fines.

Operator-friendly unit with flywheel covers

Operator-friendly unit with flywheel covers, spacious and accessible platforms make the daily operation and maintenance simpler, safer, and faster.

Removable electrical control panel

Removable electrical control panel can be located on the ground during operation.

Heavy duty chassis beams

Heavy duty chassis beams, strength analysis on structural parts and quality components for durability.

Low cost per tonne

Low cost per tonne due to electric operation .

Capable of operating

Capable of operating in the most hostile environments.

Mobile Jaw Crusher TECHNICAL SPECIFICATIONS

| Model | Jaw Size | Feed Opening | Feeder size | Belt Width | Power requirement (HP) |

|---|---|---|---|---|---|

| AJC30 | 24x12 | 300mm | 10’x3’ | 500mm | 60HP |

| AJC60 | 30X15 | 375mm | 10’x3’ | 500mm | 75HP |

| AJC100 | 32x22 | 500mm | 10’x3’ | 600mm | 100HP |

| AJC150 | 36x30 | 650mm | 14’x4’ | 800mm | 125HP |

Mobile Screening Unit

These screens provide exceptional screening capabilities and have proven their effectiveness in the production of high quality aggregates,and are the optimal choice if you want to move the plant from one site to another periodically.

We offer a wide range of portable screens to fulfil your screening needs, designed with many features aimed at high capacity production and ease of operation. With many advanced design features common throughout this range, all models combine mobility and flexibility, with high quality production, maximum uptime and low cost per tonne operation.

SALIENT FEATURES of Mobile Screening Unit

Highly efficient and accurate

Highly efficient and accurate on board 2,3 or 4 deck screens for product classification.

Material can be fed

Material can be fed by conveyor belt from a crusher or through a separate feed hopper to the screen.

Able to operate

Able to operate in open or closed circuit.

Premium quality components

Premium quality components for durability and wear lined impact zones.

Quick and easy replacement

Quick and easy replacement of wear parts, which keeps your equipment productive with minimal downtime.

hard and abrasive rock

Built for hard and abrasive rock.

Heavy duty chassis beams

Heavy duty chassis beams, strength analysis on structural parts and quality components for durability.

Mobile Screening Unit TECHNICAL SPECIFICATIONS

Have a look at our range of Mobile Screening Unit with detailed technical data below. Feel free to contact us if you require more specific information or a unique solution for your needs. Our engineers will be happy to assist with your project.

| Model | Screen Size | Screening Area | Range | Belt Width | Power requirement (HP) |

|---|---|---|---|---|---|

| AC80 | 14’x5’ | 70sq.ft | 50-100 TPH | 500mm | 15-25HP |

| AC120 | 16’x5’ | 80sq.ft | 80-150TPH | 600mm | 20 -30 HP |

| AC200 | 18’x5’ | 90sq.ft | 150 - 250TPH | 600mm | 25 - 40 HP |

Portable Two-Stage plants

SALIENT FEATURES of Portable Two-Stage plants

High Performance and Reliability

Agarwalla MIC100 is a complete processing unit fully assembled on a single trailer frame. Featuring the 10’x3' grizzly feeder, highly reliable and productive 32”x22" jaw for primary crushing, 42”x8” Jaw for secondary crushing, closed circuit belt conveyors for excellent feed to the MS 14’x5' vibrating screen, it offers a highly versatile, highend capacity plant capable of processing 1-3 products at a low cost-per-tonne operation.

High Performance and Reliability

Agarwalla MIC100 is a complete processing unit fully assembled on a single trailer frame. Featuring the 10’x3' grizzly feeder, highly reliable and productive 32”x22" jaw for primary crushing, 42”x8” Jaw for secondary crushing, closed circuit belt conveyors for excellent feed to the MS 14’x5' vibrating screen, it offers a highly versatile, highend capacity plant capable of processing 1-3 products at a low cost-per-tonne operation.

Heavy duty chassis beams

Heavy duty chassis beams, strength analysis on structural parts and quality components for durability.

reliability and minimal maintenance

All onboard components are electrically driven giving reliability and minimal maintenance .

Capable of operating & Simple and efficient

Capable of operating in the most hostile environments and Simple and efficient, designed for trouble free operation.

Removable electrical control panel

Removable electrical control panel to be located on the ground during operation.

multiple emergency stop buttons

Safety guards for crusher drives and multiple emergency stop buttons for safe operation .

excellent access for service and maintenance

Maintenance platforms with handrails and access ladders provide excellent access for service and maintenance.

minimizing environmental impact

Low emissions due to electrical operation, minimizing environmental impact.

Portable Two-Stage plants TECHNICAL SPECIFICATIONS

| Capacity | 100TPH |

| M/c Size | 32"X22" |

| M/c Size | 42"X08" |

| Screen Size | 15'X4' |

| Approx Weight | 50Tons |

| Motor HP | 200HP |

| Tyres | 8Nos |

| Landing Legs | 3 Sets |

| Skid Legs | 5Nos |

| Control Panel | Attached |

| Product Conveyores | 3Nos |

| Transfer belts | 2Nos |

| Chassis Size | 45' long |

| Output | -63mm |

| Lead time | 3-4 days |